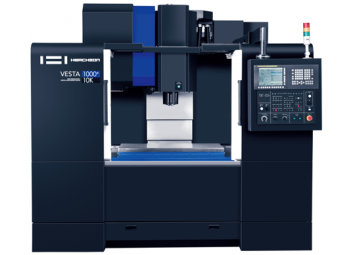

Introducing the faster, more precise, more reliable vertical machining center for component machining.

Hwacheon's machining software monitors many environment and machining condition related variables and makes optimized adjustments for the best quality results at optimum work efficiency.

Specifications

| Stroke (X/Y/Z) | 660/430/400mm |

| Feedrate Rapid Speed (X/Y/Z) | 36/36/30m/min |

| Table Size (Width x Length) | 720x400mm |

| Table Loading Capacuty | 560kg |

| Max. Spindle Speed | 10000rpm |

| Spindle Motor Power | 15/11kW |

| Type of Tool Shank | MAS-403 BT40 (Opt. CAT40) |

| Tool Storage Capacity | 20 |

| Floor Space (Length X Width) | 3130x1980mm |

Product Description

- High-speed motor-integrated spindle: 10000rpm

- Rapid feed(X/Y/Z): 36/36/30mm/min

- Roller LM Guide design for all axes

- Coolant through spindle 30 bar standard

SUPER FAST ROUGHING AND ULTRA PRECISE FINISHING PERFORMANCE

The VESTA series of machining centers are the result of Hwacheon's technological innovation.

These high-performance machines are optimized for job shop machining applications, with the easy-to-use interface to maximize your productivity. HTLD increases the life of your tools; HECC provides perfect contour control for better machining efficiency; OPTIMA controls the feed rate and HTLD adjusts the temperature in real time. To minimize thermal displacement and to increase the life of the spindle assembly, the spindle unit is grease-lubricated and jacket cooled. The advanced feed drive complements the spindle for highly precise machining result every time. The super tough roller guide keeps its precision even at high speeds, and offers a variety of options for your convenience. Last but not least, VESTA's advanced chip removal and lube separation system help to save cost.

USER FRIENDLY DESIGN, A WIDE RANGE OF OPTIONAL FEATURES

The VESTA-660 system offers a user friendly design and a wide variety of useful options for practical applications, so you can concentrate on what you do best: creating quality products without losing your valuable time to the worries of machine failure and safety. A wide variety of performance upgrade options are available for faster, more precise machining.