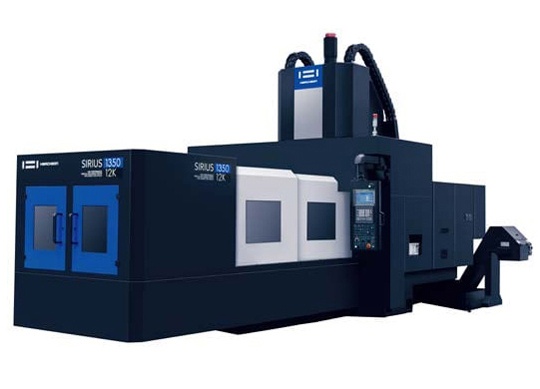

SIRIUS-1350 is a precision machining center specialized for medium to large size mold & die production. With Hwacheon's unique machining software built in, it provides a geometrical accuracy that satisfy every customer with improved productivity. It is especially suited for high quality mold machining which requires a superb surface finish like machining "Head Light Bezel".

Specifications

| Stroke (X/Y/Z) [mm] | 2550/1350/750 |

| Rapid Speed (X/Y/Z) [m/min] | 16/16/16 |

| Working Surface [mm] | 2800 x 1250 |

| Table Loading Capacity [kg] | 8000 |

| Max. Spindle Speed [rpm] | 12000 (8000 rpm, 8000rmp high torque) |

| Spindle Motor [kW] | 30/25 |

| Type of Tool Shank | BBT-50 (Opt.:CAT-50, HSK-A100, SK-50) |

| Tool Storage Capacity [ea] | 40(Opt: 60) |

| Floor Space (L x W) [mm] | 8120 x 4340 |

| NC Controller | Fanuc 31-B |

Product Description

Product Description

High quality machining for large size mold applications

- Load capacity of maximum 8 tons

- Applied precision enhancement technology of a Box Way feeding system

- Minimized vibration by separating the source of vibration (Oil Cooler)

Capable of large size mold precision & die

- Able to set various sizes of work material

- Applicable tool length of maximum 500 mm

- Wide door opening range for easier loading/unloading of large materials

- Configurable magazine options according to tool specifications and requirements