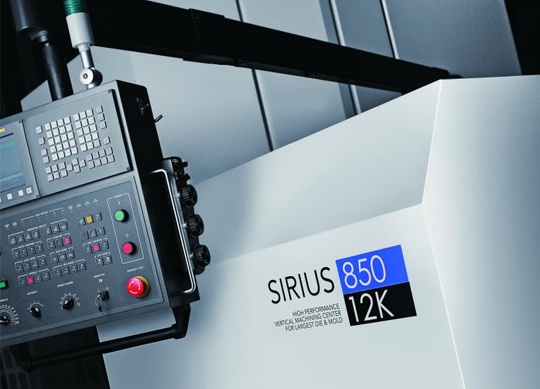

Worldwide professional count on SIRIUS-850 Box Way Machining Center

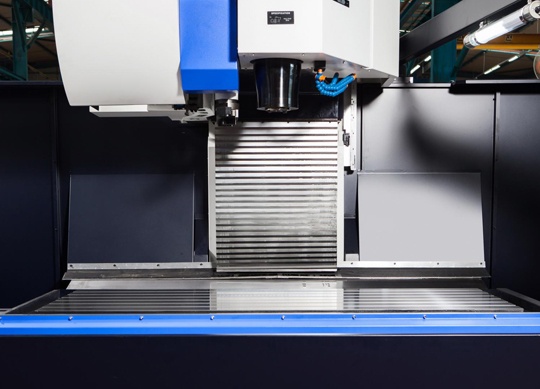

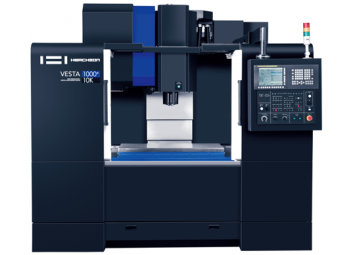

The SIRIUS-850 vertical machining centers incorporates highly rigid box way slide design for all axes for absolute consistent work result. The rigid high-output spindle delivers strong and efficient machining performance during roughing and at high speed, and the user-friendly design will make your work more productive.

Specifications

| Stroke (X/Y/Z) | 2000/850/750mm |

| Feedrate Rapid Speed (X/Y/Z) | 16/16/16m/min |

| Working Surface | 2150 x 850mm |

| Table Loading Capacity | 4000kg |

| Max. Spindle Speed | 8000rpm (12000rpm) |

| Spindle Motor | 30/25kW (40/34kW) |

| Type of Tool Shank | BT-50 (Opt. BBT-50,CAT-50) |

| Tool Storage Capacity | 24 |

Product Description

- 8000rpm or 12000rpm high-speed spindles to choose from

- Oil-jet cooled motor-integrated spindle (30/25kW)

- Stroke (X/Y/Z): 2,000/850/750mm

- High rigid box way design for all axe

HIGH-SPEED STABILITY FOR LARGE-SIZE APPLICATIONS

Heavy Duty Machining

SIRIUS-850 vertical machining centers have been trusted by the professionals allover the world for more than twenty years. The box way slide design guarantees persistent, quality result every time, and the air levitation feed system allows for gentle yet precise feed. The spindle integrates a powerful, high-performance motor to deliver perfect machining result for large-size workpiece. The large work area allows for easy clamping & unclamping of large workpieces the full-enclosure cover keeps your workspace safer and cleaner. Hwacheon's proprietary machining

software options, and a wide selection of options and convenient features will help you to be productive and efficient.

MACHINING SOFTWARE

The Hwacheon Machining Software Components

The Hwacheon's developed machining software monitors different variables related to the work environment and machining conditions automatically makes adjustments for best quality results and optimum work efficiency.

USER FRIENDLY DESIGN, A WIDE RANGE OF OPTIONAL FEATURES

SIRIUS-850 offer user friendly design and a wide variety of useful options of practical applications, so you can concentrate on what you do best: creating quality products-without losing your valuable time to the worries of machine failure and safety. A wide variety of performance upgrade options are available for faster, more precise machining.