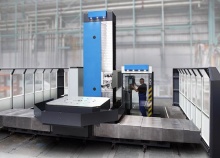

Škoda HCW 1–4 Series Horizontal Boring and Milling Machine

Image

HIGH TORQUE FULLY HYDROSTATIC MACHINE

This gives excellent results during machining process while taking huge chips as well as during very accurate fine machining on the customer’s components, meeting the highest demands.

HIGH TORQUE FULLY HYDROSTATIC MACHINE

This gives excellent results during machining process while taking huge chips as well as during very accurate fine machining on the customer’s components, meeting the highest demands.