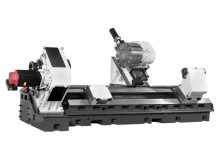

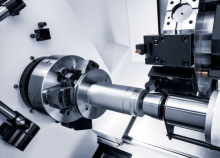

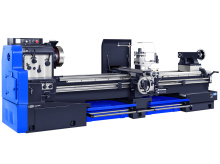

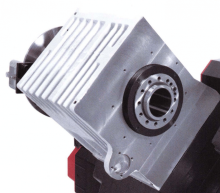

HWACHEON Mega 72 Heavy Duty Horizontal CNC Lathe

Image

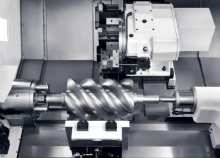

HIGH ACCURACY

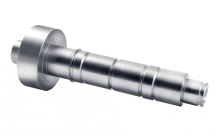

- Adoption of ball screw and servo motor

- Easy checking for spindle speeds by attachment of spindle position encoder

- Guarantee of repeatability ±5° by adoption of curvic toolpost

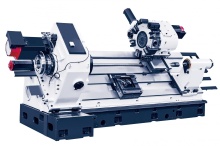

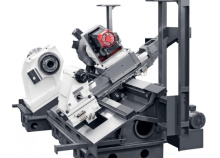

UTMOST CONVENIENCE

HIGH ACCURACY

- Adoption of ball screw and servo motor

- Easy checking for spindle speeds by attachment of spindle position encoder

- Guarantee of repeatability ±5° by adoption of curvic toolpost

UTMOST CONVENIENCE

- Excellent operation & easy loading/ unloading work piece by convenient operation panel

- Semiautomatic tailstock feeding device

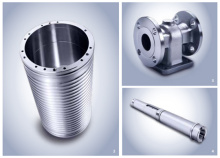

HEAVY DUTY CUTTING